New & Next

NSYS

Leader of Global Machine

Vision Inspection Equipment

Vision Inspection Equipment

Business

secondary battery

The only company in Korea capable of providing inspection equipment

for all secondary battery processes

for all secondary battery processes

- Electrode Process

- A step where cathode and anode materials are applied

on battery and cut into certain sizes

-

- Coater Inspector

- A product for inspection on surface defects including detachment in another

and cathode coating part, mismatching, and coating width

-

- Roll-Press & Slitter Surface Inspector

- A product for inspecting on the surface applied with roll-press

and slitter after coating to inspect on the defect

-

- Insulated Coating (Overlay) Inspector

- A product that inspects on insulated coating status after adding insulated coating (yellow color)

on the end part for safety after electrode coating (black color)

-

- Small Battery (Insulated Coating) Inspector

- A product that inspects on small battery to manage surface defect

and defect records of material applied with insulated coating

-

- Perforation Inspector

- A product that inspects on the product’s pin hole (perforation)

defects through vision inspection

- Assembly Process

- A step where plates are assembled

in the form of can or pouch cell

-

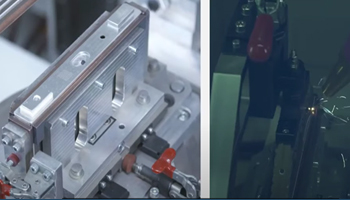

- Ultrasonic Welding Inspector

- A product that inspects on the defects after welding of J/R, anode,

and cathode in battery form creation step

-

- Laser Welding Inspector

- A product that inspects on the defects and tears in welding of cap plate, anode, and cathode

-

- Front Tape Height Inspector

- A product that measures the distance (height)

from the base level to tape in order to inspect on proper positioning of the tape

-

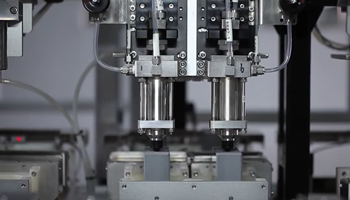

- Seal Pin Welding Inspector

- A product that inspects on defects by measuring the welding status

of seal pin used for sealing after electrolyte injection

-

- Spatter Inspector

- A product that inspects on spatter (particle that came off from the surface)

that happens after laser welding

-

- Polymer Sealing Thickness Measurer

- A product that measures the thickness of sealing in polymer cell’s anode,

cathode, upper part, and side part

-

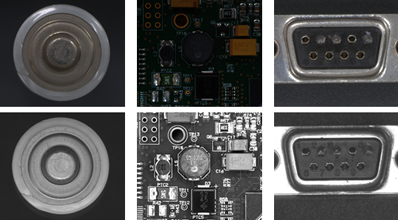

- Cylindrical Visual Inspector

- A product that inspects on press, dent, scratch, foreign substance,

and contamination of cylindrical battery

-

- Lamination Inspector

- A product that inspects in alignment status

and fixing tape status after laminating two layers during J/R production

-

- J/R Width Inspector

- A product that inspects on width after rolling after laminating two layers during J/R production

-

- 3D Can-Cap Inspector

- A product that inspects on welding status and height

of the battery cell assembled by using 3D camera

-

- Tack Welding Inspector

- A product that inspects on tack welding status after the tack welding on can cap

(to prevent bending or twist of structure)

-

- Polymer Figure Inspector

- A product that inspects on alignment status and fixing tape status

after laminating two layers during J/R production

-

- Polymer Cell-Checker

- A product that inspects by matching the polymer cell status data and actual information

- Activation Process

- A step for sorting defects in completed battery

and granting battery grade

-

- Upper Visual Inspector

- A product that mainly inspects on upper part (terminal part)

of a square-shape cell battery

-

- Tape Height Inspector

- A product that measures the height and width of a square-shape cell battery

-

- Five-Sided Visual Inspector

- A product that inspects defects (bubble, scratch, foreign substance, etc.)

on five sides of a square-shape cell battery

-

- DMC Label Inspector

- A product that inspects the adhesion status and location of DMC label of a square-shape cell

-

- Seal Pin Inspector

- A product that inspects on pin hole and electrolyte defects for welding of a square-shaped cell

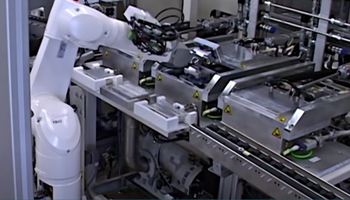

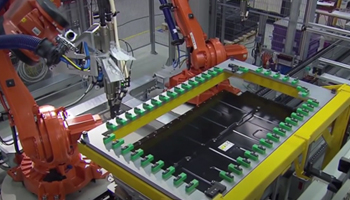

- Module and Packing Process

- A step for welding each battery and having batteries mountable on electric vehicle

-

- Upper/Side Welding Inspector

- A product that inspects on welding status of upper part

and side part of a completed square-shape cell battery module

-

- Lower Part Welding Inspector

- A product that inspects on welding status of lower part of a completed square-shape cell battery module

-

- End-Plate Inspector

- A product that inspects on welding status and measurement of the parts attached

to the sides of a completed square-shape cell battery module

Holds technical competence for each secondary battery process

-

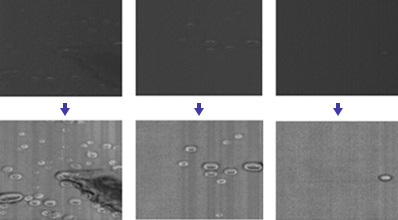

- LED optical lighting-based image processing technology

- Easy to acquire uniform image compared to existing method and higher defect utilization rate↑

-

- Preprocessing algorithm-based fault inspection

- Higher inspection reliability

-

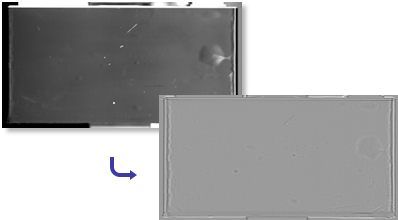

- 2.5D algorithm image processing technology

- Reduces cost price by 30% and increases inspection reliability